【研究意义】荔枝(Litchi chinensis Sonn)果型漂亮、色泽鲜艳、口感极好,深受国内外消费者喜爱,在我国南方亚热带地区广泛栽培,在国内外水果市场上极具竞争力[1-2]。荔枝也被认为是最难保鲜贮藏的水果之一,保鲜难已成为制约荔枝产业发展的主要问题之一[3-4]。荔枝采收期集中在高温多湿的夏季,采后果实生理作用旺盛,果实腐烂变质和果皮褐变影响荔枝贮运保鲜期[5]。【前人研究进展】荔枝果皮褐变与果实失水具有密切关系。荔枝果实的失重率主要由果皮失水引起,当果皮失水超过本身含水量50%时,果皮即表现褐变症状,荔枝果皮褐变与果皮失水率呈明显的正相关[6-10]。可见,无论是低温贮运还是常温贮运或销售,防止或减缓果实失水是荔枝果实保鲜中的关键措施。最有效防止果皮失水的措施是保鲜袋保湿包装,然而包装袋的高湿度往往促使果实腐烂[1,5,8]。以往研究较多探讨了多种技术延长荔枝的保鲜期,如低温自发气调保鲜技术、硫熏保鲜技术、气调保鲜技术、涂膜保鲜技术、臭氧保鲜技术等[11-15]。在生产上广泛应用的主要是低温自发气调保鲜技术、硫熏保鲜技术两类。由于硫熏处理导致的硫残留潜在隐患常引起消费者担忧,目前在国内市场上受到诸多限制,我国荔枝采后主要采用薄膜保鲜袋包装结合低温贮运。【本研究切入点】荔枝果皮褐变的主要原因在于果皮失水,因此在贮运过程中,采用保鲜膜保湿是必须措施。但在荔枝保鲜袋包装中,前期果实产生水蒸气的速率远远大于水汽透过保鲜袋的速率,导致大量水分聚集在包装内,从而有利于腐败微生物繁殖,促进荔枝腐烂[16]。随着贮藏时间延长,包装袋内里的水汽逐渐透过薄膜袋丧失,袋内湿度又会下降,包装袋内湿度水平过低又会促进果皮褐变。因此,如何调控采后荔枝在自发气调贮藏中包装袋内的相对湿度,成为解决低温自发气调贮藏的关键技术难题。聚丙烯酰胺(Polyacrylamide,PAM)树脂能吸收比自身重数倍的水分,具有反复吸水、放水功能,在外界环境较干燥时,前期已吸收水分的PAM则会缓慢释放水分,从而起到“微型水源”的作用,目前已在农业园林的土壤改良、干旱保水等领域得到广泛应用[17-19]。【拟解决的关键问题】利用PAM吸湿能力强兼具有吸水与放水功能的特点,探讨荔枝果实在低温贮藏前期包装袋内湿度过高时,PAM能否迅速吸收过多水分,而当贮藏后期袋内湿度过低时,PAM能否起到释放水分提高湿度的效果,为研发适合荔枝的湿度调控以及荔枝贮藏保鲜技术提供参考。

1 材料与方法

1.1 试验材料

供试材料为采自广州市从化果园的荔枝怀枝(Litchi chinensis Sonn. cv. Huaizhi)果实。采摘后2 h内运回广东省果蔬保鲜重点实验室,挑选大小、成熟度、色泽一致的无病、无虫、无伤果实备用。

1.2 试验方法

试验于2019 年在华南农业大学园艺学院进行。荔枝果实先用1 g/L漂白粉溶液浸泡2 min,然后用1 g/L咪鲜胺溶液浸泡2 min,取出待其表面水干,备用。所有样品均分散放入果篮,然后用0.02 mm 聚乙烯(PE)袋包装。平均分为两组,一组为对照;一组为聚丙烯酰胺(PAM)湿度调节处理,放置用纱布包好的PAM湿度调节剂(10 g/kg荔枝果实)于果篮中。置于温度5 ℃、相对湿度约66%的冷库中贮藏,3个重复(每50个果实放置一个果篮),将湿度计置于包装内,记录每小时湿度变化。每隔7 d取样1次,并调查果皮褐变和腐烂变化情况。取样时将果皮和果肉分开,分别立即用液氮急冻,保存于-80 ℃冰箱,每个时间点取样,3次重复。

1.3 测定指标及方法

腐烂率:观察每个处理果实长霉流汁的情况,随机取荔枝果实不少于30个,统计腐烂果实数量。

病情指数:参照Huang等[20]方法分级:0级,果皮无病斑;1级,病斑面积小于总面积 25%;2级,病斑面积大于25%、小于 50%;3级,病斑面积大于 50%、小于75%;4级,病斑面积大于75%。

果皮褐变指数:参照Scott等[21]方法确定荔枝果皮褐变级数,随机取不少于30个荔枝果实用于统计褐变指数。![]() 其中0级果为全红,5级果为全褐。

其中0级果为全红,5级果为全褐。

果皮花色素苷:参照张昭其等[22]方法提取,采用pH 示差法检测。

果实失重率:固定3盒荔枝果实用于记录贮藏期间果重变化。

果皮含水量:取10个鲜果皮样品圆片,称重后放于直径4 cm的铝盒中,烘箱烘干直至铝盒加果皮的重量不再变化。称量果皮烘干后的重量,失去重量即为果皮的水分含量。

果皮厚度:随机取10个荔枝果实果皮,使用游标卡尺(上海九量)测定每个荔枝果实相同部位的果皮厚度,取平均值。

相对电导率:参照张昭其等[22]方法,用直径1 cm的打孔器取10个果皮圆片,双蒸水清洗后用纸巾吸干,加入装有20 mL双蒸水的离心管中,20 ℃、50 r/min、2 h后,称重,用DDS-ЏA型电导仪测电导率R1。将离心管放入微波炉中加热使管内水沸腾,冷却到20 ℃,加入双蒸水将其调到加热前的重量,再用电导仪测量R2。计算果皮的相对电导率,3次重复。

试验数据采用SPSS22.0进行统计与分析,采用Excel 2016软件作图。

2 结果与分析

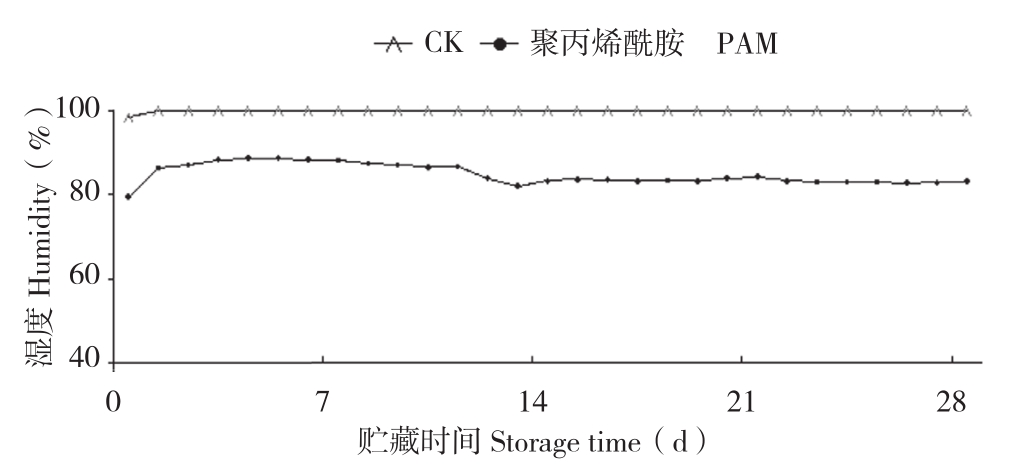

2.1 PAM处理对荔枝贮藏期间包装内湿度的影响

由图1可知,低温贮藏期间,对照荔枝果实包装袋内的相对湿度在贮藏1 h后达到99.9%,且一直维持高水平;PAM处理的包装袋内湿度明显低于对照,波动范围为80%~90%,表明聚丙烯酰胺处理能降低贮藏初期荔枝果实包装贮藏中的相对湿度。

图1 PAM处理对荔枝贮藏期间包装内部湿度的影响

Fig. 1 Effects of PAM treatment on the internal humidity of the package during storage of litchi

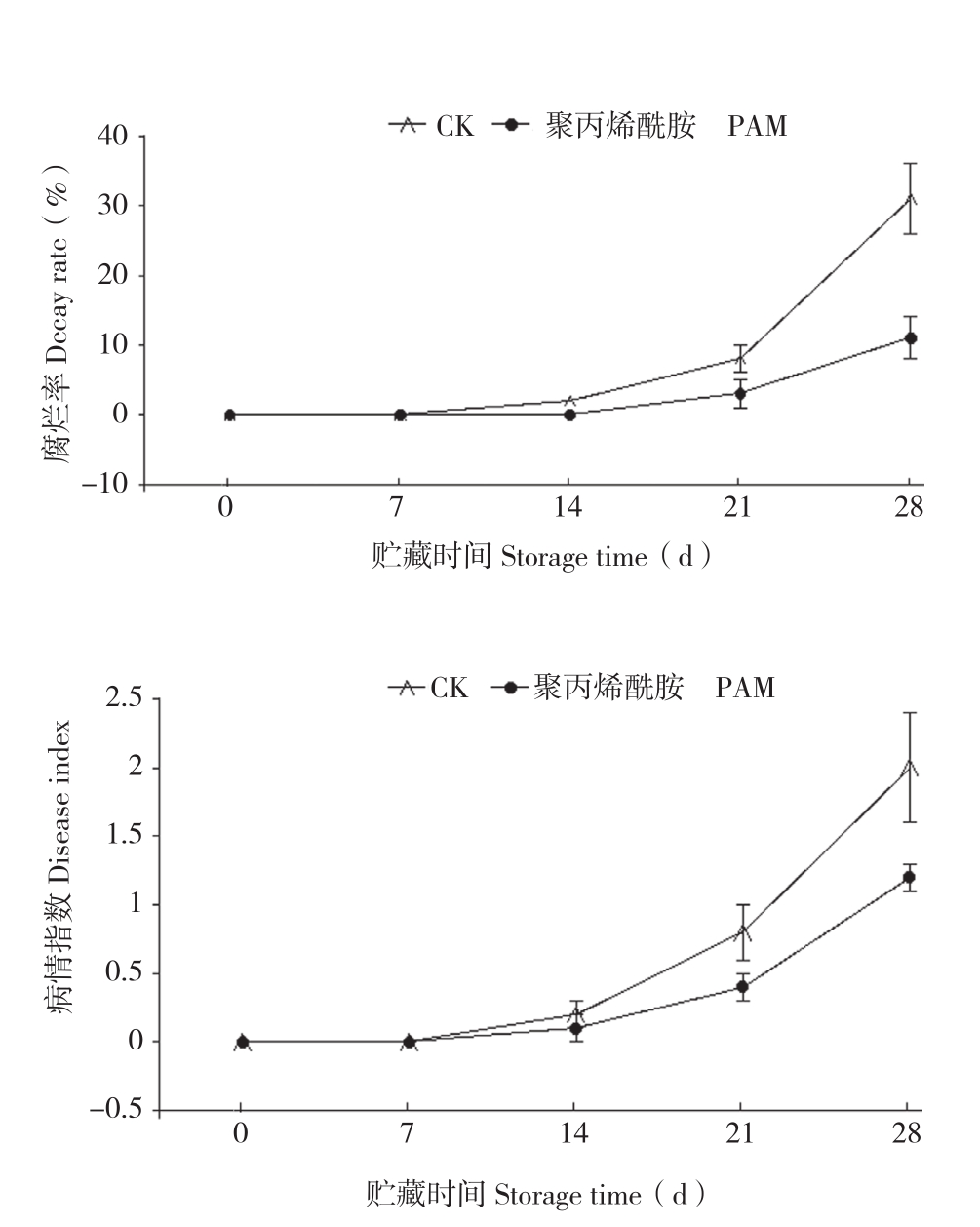

2.2 PAM处理对荔枝果实腐烂率和病情指数的影响

由图2可知,低温贮藏期间,对照和PAM处理的荔枝果实腐烂率均呈上升趋势,对照果实在贮藏14 d后开始腐烂,之后腐烂率快速上升,贮藏21 d升至8%,至28 d时达到31%。而处理的荔枝果实腐烂率在贮藏28 d仅为11%,显著低于对照,果实病情指数也呈同样规律。表明聚丙烯酰胺作为湿度调控处理,能有效减缓病原菌的繁殖生长,有效降低荔枝果实的腐烂率和病情指数。

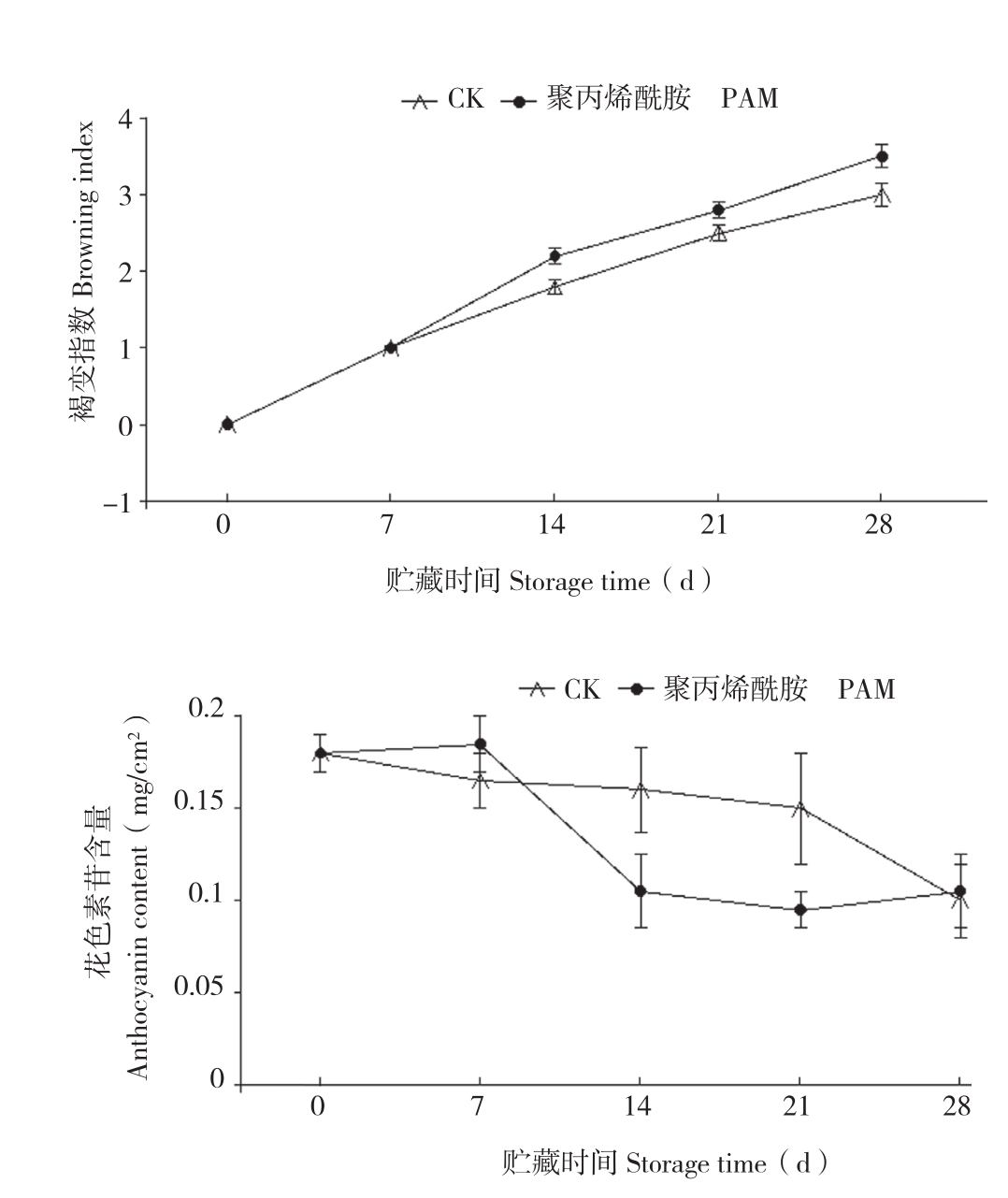

2.3 PAM处理对荔枝果皮褐变指数和花色素苷含量的影响

由图3可知,低温贮藏期间,对照和PAM处理的荔枝果实褐变指数均呈上升趋势,贮藏14 d 时,均接近2;与对照相比,贮藏14 d后PAM处理的荔枝果皮褐变指数均略高于对照。从果皮花色素苷含量的变化也可看出,贮藏14、21 d时,PAM处理的荔枝果实果皮花色素苷含量均比对照低,但贮藏28 d后两者无显著差异。

图2 PAM处理对荔枝果实腐烂率和病情指数的影响

Fig. 2 Effects of PAM treatment on decay rate and disease index of litchi fruits

图3 PAM处理对荔枝果实褐变指数和果皮花色素苷含量的影响

Fig. 3 Effects of PAM treatment on browning index and pericarp anthocyanin content of litchi fruits

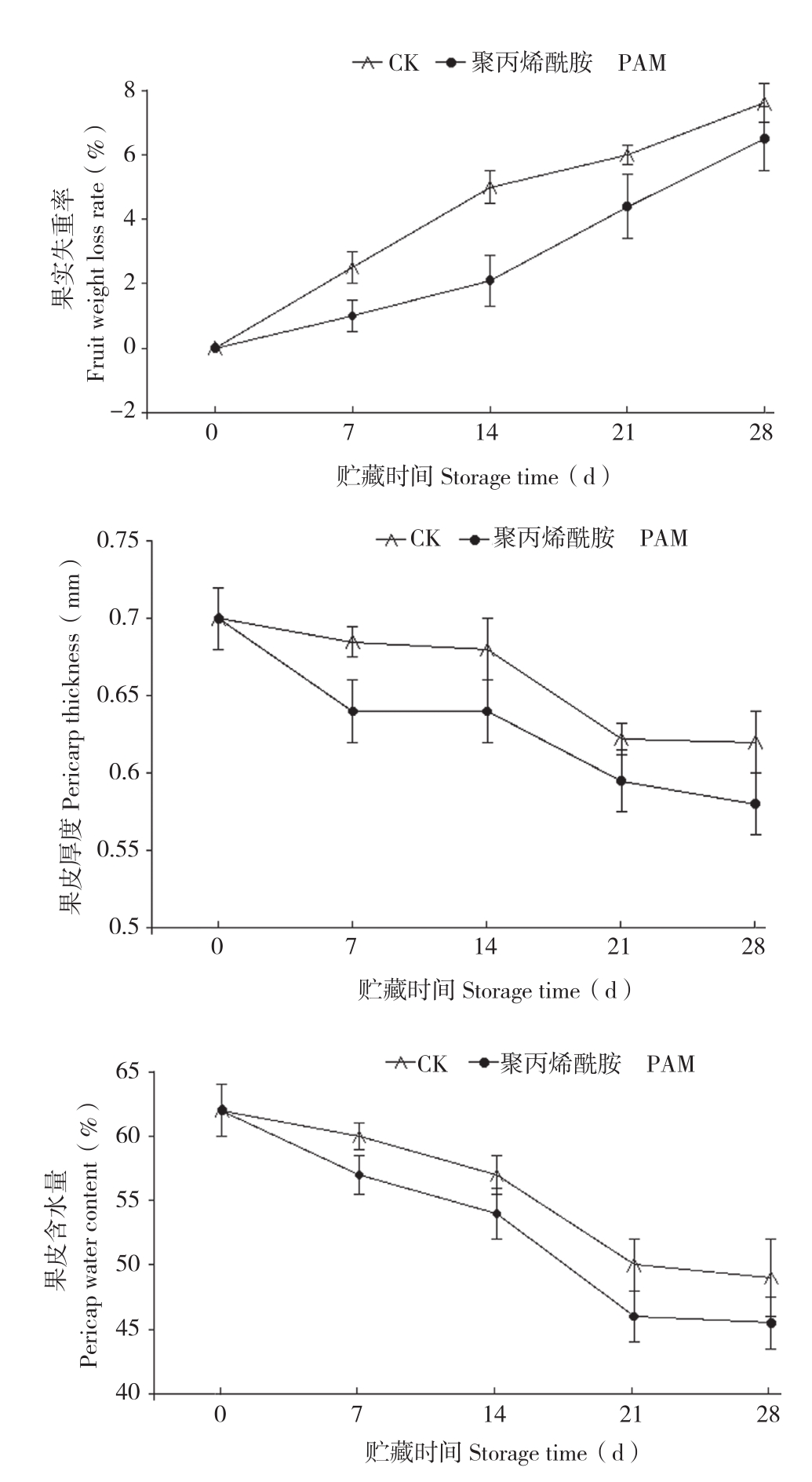

2.4 PAM处理对荔枝果实失重率、果皮厚度和果皮含水量的影响

蒸腾作用和呼吸作用均可导致果实在贮运过程中质量损失,但蒸腾失水占据主要部分,因此果实失重率可基本反映其在贮运过程中蒸腾失水的快慢。由图4可知,低温贮藏期间,随着贮藏时间延长,对照和PAM处理的荔枝果实失重率均呈上升趋势,贮藏7 d后,PAM处理果实的失重率均比对照的高。荔枝果实失水以果皮失水为主,果皮厚度和含水量反映了果皮失水程度,随着贮藏时间延长,对照和PAM处理的果皮厚度和果皮含水量都逐渐下降;贮藏28 d时,对照的果皮厚度由0.7 mm降到0.62 mm,果皮含水量由62% 降到49%,而PAM处理的果实下降速度比对照稍快,果皮厚度降到0.58 mm,含水量为45%。表明PAM处理在有效降低包装袋内相对湿度的同时,也促进果实失水失重,表现在果皮更薄、果皮含水量更低。

图4 PAM处理对荔枝果实失重率、果皮厚度和果皮含水量的影响

Fig. 4 Effects of PAM treatment on weight loss rate of litchi fruits, pericarp thickness and pericarp water content

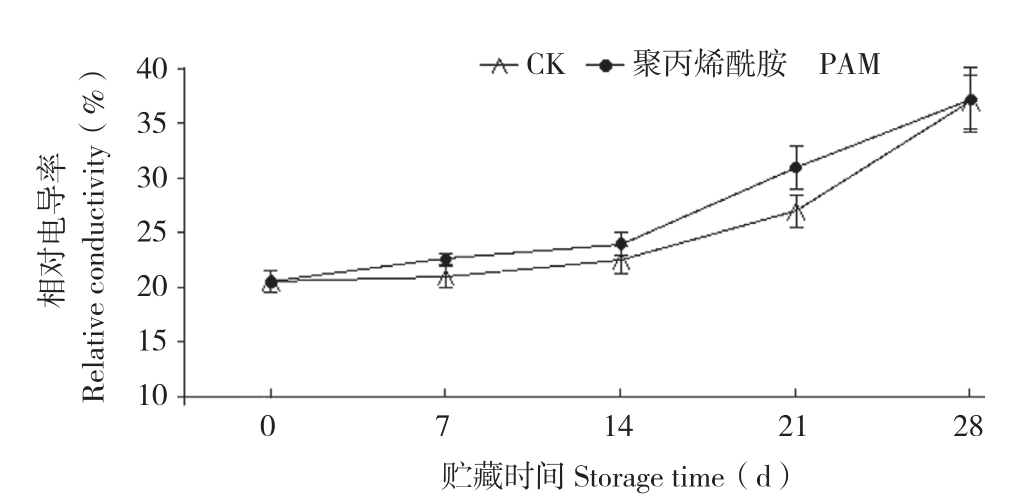

2.5 PAM处理对荔枝果实细胞膜透性的影响

由图5可知,低温贮藏期间,对照和PAM处理的荔枝果实果皮相对电导率均呈上升趋势。贮藏前期上升趋势缓慢,贮藏14 d 后,相对电导率的上升速率加快,同时PAM处理果实的相对电导率略高于对照。贮藏28 d后,其电导率与对照相近,均接近37%,表明PAM处理在低温贮藏期间并没有加速果实衰老。

图5 PAM处理对荔枝果实细胞膜透性的影响

Fig. 5 Effect of PAM treatment on cell membrane permeability of litchi fruits

3 讨论

聚丙烯酰胺(PAM)是新型高分子有机吸湿材料,吸收水分能力远高于一般无机湿度调控材料,吸湿容量可高达其本身重量的数倍。目前,PAM作为一种无毒环保产品,已被广泛应用于饮用水处理[23-24]。另外,PAM还用于改良土壤,其保土保水保肥效果明显,可促进粮食增产[25],应用前景广阔。本文首次在采后荔枝聚乙烯薄膜保鲜袋包装中,研究了利用PAM的吸水放水功能平衡包装袋内的湿度环境,取得了一定效果。已有研究表明,采用硅胶、活性炭、皂土、无水氯化钙、活性氧化铝粉和膨润土等无机吸湿材料对气调包装袋中香菇、辣椒、双孢蘑菇、金针菇等进行湿度调控处理,可起到较好保鲜效果,能有效减缓包装袋内果蔬的腐烂[26-29]。但无机吸湿剂的吸湿容量仅为自身重量的10%~30%,且只起到单一吸湿作用,环境湿度低时不能释放所吸收水分,因此很容易过度添加使包装袋内果蔬所处湿度环境过低,导致果蔬失水严重[26-29]。PAM吸湿能力强,吸水量可达本身重量的数倍,并具有反复吸水、放水功能,在外界环境较干燥时,前期已吸收水分的PAM又会缓慢地释放出水分,从而可起到“微型水源”的作用[17-19]。针对荔枝自发气调贮藏中前期包装袋内湿度过高、后期湿度又过低这一特点,利用PAM作为湿度调控剂有利于维持荔枝包装内环境的湿度平衡,从而有望解决荔枝贮藏保鲜过程果实腐烂与果皮褐变这一矛盾。

结合荔枝果实腐烂率、病情指数、褐变指数、失重率等数据可知,与对照果实相比,以聚丙烯酰胺树脂为材料的湿度调控处理能有效降低采后荔枝在低温自发气调贮藏过程中的果实腐烂率和病情指数,但也在一定程度上提高了荔枝果皮褐变指数,促进果皮失水。虽然本实验未能很好地平衡荔枝低温自发气调贮藏中果实腐烂与果皮褐变这一主要矛盾,但显示了以PAM为吸湿剂的湿度调控处理在荔枝贮运中的应用前景。荔枝包装袋中的湿度取决于包装袋的材质、厚度及透水透气性、果实的蒸腾失水量及呼吸作用、果实装载量等。荔枝成熟于高温多湿季节,在采后贮运过程中仍进行旺盛的生理代谢活动,其中蒸腾作用和呼吸作用最为显著。因此无论是低温贮运还是常温贮运,袋内相对湿度均迅速达到饱和,从而形成了有利于腐败微生物繁殖的高湿环境[30]。厚的保鲜袋虽然有利于维持高湿度,但易促进果实腐烂,薄的保鲜袋又易导致后期湿度过低促进荔枝果皮褐变,因此在保鲜袋内添加合适的湿度调控剂应是可行措施之一。

4 结论

聚丙烯酰胺(PAM)处理有利于降低荔枝低温自发气调贮藏过程中果实的病情指数和腐烂率,但在一定程度上提高了果实的褐变指数及贮藏过程中的失重率、果皮膜透性,降低荔枝果实含水量和果皮花色素苷含量。本研究结果表明,利用PAM吸湿能力强兼具有吸水与放水功能的特点,筛选出合适剂量的PAM结合保鲜薄膜厚度可以较好解决荔枝贮运保鲜过程中果实腐烂与果皮褐变这一矛盾。以PAM为基础的复合湿度调控剂结合不同厚度保鲜膜的包装,对荔枝果实贮藏环境相对湿度及果实褐变、腐烂和品质的影响尚需进一步研究。

[1] 张长勇,马锞,徐匆,罗华健,黄应维,罗诗,胡文锋.荔枝采后腐败褐变机理及保鲜技术研究进展[J]. 热带作物学报,2013,34(8):1603-1609. doi:10.3969/j.issn.1000-2561.2013.08.034.ZHANG C Y,MA K, XU C,LUO H J,HUANG Y W,LUO S,HU W F.Research progress of postharvest browning and decay mechanisms and preservation technique of litchi[J]. Chinese Journal of Tropical Crops, 2013,34(8):1603-1609. doi:10.3969/j.issn.1000-2561.2013.08.034.

[2] 刘佩,韩冬梅,莫蔼妍,武惠桃,罗焘,郭晓萌,吴振先.荔枝果实复合保鲜剂的筛选及其常温保鲜效果的研究[J]. 热带作物学报,2020,41(1):175-183. doi:10.3969/j.issn.1000-2561.2020.01.024.LIU P,HAN D M,MO A Y,WU H T,LUO T,GUO X M,WU Z X.Screening of complex preservative and its preservation effect on litchi fruits at room temperature[J]. Chinese Journal of Tropical Crops, 2020,41(1):175-183 doi:10.3969/j.issn.1000-2561.2020.01.024.

[3] BRYANT P H.A model of postharvest moisture loss under air currents to reduce pericarp browning of litchi(Litchi chinensis Sonn.)[J].Postharvest Biology and Technology, 2012,73:8-13. doi:10.1016/j.postharvbio.2012.05.006.

[4] WU Y J,LIN H T,LIN Y F,CHEN Y H,WANG H,SHI J, XUE S,HUNG Y C.Effects of biocontrol bacteria bacillus amyloliquefaciens LY-1 culture broth on quality attributes and storability of harvested litchi fruit[J]. Postharvest Biology and Technology, 2017,132: 81-87.doi:10.1016/j.postharvbio.2017.05.021.

[5] KUMARI P,BARMAN K,PATEL V B,SIDDIQUI M W,KOLE B.Reducing postharvest pericarp browning and preserving health promoting compounds of litchi fruit by combination treatment of salicylic acid and chitosan[J]. Scientia Horticulturae, 2015,197:555-563. doi:10.1016/j.scienta.2015.10.017.

[6] 邓义才,朱慧英,徐妙颜,李安妮.荔枝果皮褐变与果实水分、呼吸变化的关系[J]. 广东农业科学,1994,21(5):17-19.DENG Y C, ZHU H Y, XU M Y, LI A N. Relationship between pericarp browning and fruit moisture and respiration of Litchi[J]. Guangdong Agricultural Sciences, 1994,21(5):17-19.

[7] 张昭其,庞学群,季作梁,李雪萍.采后荔枝果皮褐变的研究[J].热带作物学报,1997,18(2):53-58.ZHANG Z Q, PANG X Q, JI Z L, LI X P. Pericarp browning of postharvest litchi fruit[J]. Chinese Journal of Tropical Crops,1997,18(2):53-58.

[8] JIANG Y M,FU J R.Postharvest browning of litchi fruit by water loss and its prevention by controlled atmosphere storage at high relative humidity[J]. LWT-Food Science and Technology, 1999,32(5):278-283. doi:10.1006/fstl.1999.0546.

[9] HUANG X M, WANG H C, YUAN W Q, LU J M, YIN J H, LUO S,HUANG H B. A study of rapid senescence of detached litchi: Roles of water loss and calcium[J]. Postharvest Biology & Technology,2005,36(2):177-189. doi:10.1016/j.postharvbio.2004.12.005.

[10] RIEDERER M,ARAND K,BURGHARDT M,HUANG H,RIEDEL M,SCHUSTER A C,SMIRNOVA A,JIANG Y M.Water loss from litchi(Litchi chinensis)and longan(Dimocarpus longan)fruits is biphasic and controlled by a complex pericarpal transpiration barrier[J]. Planta, 2015, 242(5):1207-1209. doi:10.1007/s00425-015-2360-y.

[11] SIVAKUMAR D,TERRY L A,KORSTEN L.An overview on litchi fruit quality and alternative postharvest treatments to replace sulfur dioxide fumigation[J]. Food Reviews International, 2010,26(2):162-188.doi:10.1080/87559121003590516.

[13] TRAN D T,HERTOG M,NICOLA B M.Hierarchical response surface methodology for optimization of postharvest treatments to maintain quality of litchi cv. 'Thieu' during cold storage[J].Postharvest Biology & Technology, 2016,117:94-101. doi:10.1016/j.postharvbio.2016.01.006.

[14] REICHEL M,WELLHOFER J,TRIANI R,SRUAMSIRI P,CARLE R,NEIDHART S.Postharvest control of litchi(Litchi chinensis Sonn.)pericarp browning by cold storage at high relative humidity after enzyme-inhibiting treatments[J]. Postharvest Biology &Technology, 2017,125:77-90. doi:10.1016/j.postharvbio.2016.10.002.[13] JIANG X,LIN H,LIN M,CHEN Y H,WANG H,LIN Y X,SHI J,LIN Y F. A novel chitosan formulation treatment induces disease resistance of harvested litchi fruit to peronophythora litchii in association with ROS metabolism[J]. Food Chemistry, 2018, 266(15):299-308.doi:10.1016/j.foodchem.2018.06.010.

[14] 罗焘,李双双,郭晓萌,韩冬梅,吴振先.脱硫对熏硫‘黑叶’荔枝采后品质及果肉亚硫酸盐代谢的影响[J]. 食品科学,2019,40(7):246-254. doi:10.7506/spkx1002-6630-20180211-142.LUO T, LI S S, GUO X M, HAN D M, WU Z X. Effect of desulphurization on postharvest quality and sulfite metabolism in sulfur-fumigated 'Heiye' litchi fruit[J]. Food Science, 2019,40(7):246-254. doi:10.7506/spkx1002-6630-20180211-142.

[15] ALI S,SATTAR K A,ULLAH M A,ANJUM M A,NAWAZ A,SHOAIB S H M.Modified atmosphere packaging delays enzymatic browning and maintains quality of harvested litchi fruit during low temperature storage[J]. Scientia Horticulturae, 2019,254:14-20. doi:10.1016/j.scienta.2019.04.065.

[16] YANG Y C,SUN D W,WANG N N.Rapid detection of browning levels of lychee pericarp as affected by moisture contents using hyperspectral imaging[J]. Computers and Electronics in Agriculture,2015,113:203-212. doi:10.1016/j.compag.2015.02.008.

[17] 余高,陈芬,谢英荷,赵晓东,郑海霞,谭杰斌.有机无机复合保水材料对玉米苗期土壤水分及幼苗生长的影响[J]. 河南农业科学,2019,48(10):23-29. doi:10.15933/j.cnki.1004-3268.2019.10.004.YU G,CHEN F,XIE Y H,ZHAO X D,ZHENG H X,TAN J B.Effects of organic-inorganic superabsorbent polymer composites on soil moisture and growth of maize at seedling stage[J]. Journal of Henan Agricultural Sciences, 2019,48(10):23-29. doi:10.15933/j.cnki.1004-3268.2019.10.004.

[18] YAO Y,CHEN F,CHEN X,SHEN Q,ZHANG L.Data of microstructure and mechanical properties of carbon foams derived from sucrose/polyacrylamide hydrogel[J]. Data in Brief, 2016,7:117-122.doi:10.1016/j.dib.2016.02.022.

[19] PARK J B K,MEERMAN C,CRAGGS R.Continuous low dosing of cationic polyacrylamide(PAM)to enhance algal harvest from a hectare-scale wastewater treatment high rate algal pond[J]. New Zealand Journal of Botany, 2019,57(2):112-124. doi:10.1080/00288 25X.2018.1552159.

[20] HUANG Z Q,LIANG X T,HU H Y,GAO L,CHEN Y J,TONG Z F.Influence of mechanical activation on the graft copolymerization of sugarcane bagasse and acrylic acid[J]. Polymer Degradation and Stability, 2009,94(10):1737-1745. doi:10.1016/j.polymdegradstab.2009.06.023.

[21] SCOTT K J,BROWN B I,CHAPLIN G R,WILCOX M E,BAIN J M.The control of rotting and browning of litchi fruit by hot benomyl and plastic film[J]. Scientia Horticulturae, 1982,16(3):253-262.doi:10.1016/0304-4238(82)90073-5.

[22] 张昭其,庞学群,段学武,季作梁.荔枝果皮褐变过程中花色素苷含量的变化及测定[J]. 华南农业大学学报,2002,23(1):16-19.doi:10.3969/j.issn.1001-411X.2002.01.005.ZHANG Z Q,PANG X Q,DUAN X W,JI Z L.Change of anthocyanin content and its determination during lychee pericarp browning[J].Journal of South China Agricultural University, 2002,23(1):16-19.doi:10.3969/j.issn.1001-411X.2002.01.005.

[23] PARK J B K,MEERMAN C,CRAGGS R.Continuous low dosing of cationic polyacrylamide(PAM)to enhance algal harvest from a hectare-scale waste water treatment high rate algal pond[J]. New Zealand Journal of Botany, 2019,57(2):112-124. doi:10.1080/00288 25X.2018.1552159.

[24] YE S,FENG P,ZHANG W.Rapid solidification of portland cement/polyacrylamide hydrogel(PC/PAM)composites for diverse waste water treatments[J]. RSC Advances, 2020,10(32):18936-18944.doi:10.1039/D0RA03025B.

[25] 员学锋,吴普特,冯浩.聚丙烯酰胺(PA M)的改土及增产效应[J]. 水土保持研究,2002,9(2):55-58. doi:10.3969/j.issn.1005-3409.2002.02.016.YUAN X F,WU P T,FENG H.Role of polyacrylamide on soil structure and increasing yield[J]. Research of Soil and Water Conservation,2002,9(2):55-58. doi:10.3969/j.issn.1005-3409.2002.02.016.

[26] 赵东方,魏丹,周晓庆,应丽莎,张敏.复合吸湿剂对高氧气调包装香菇品质的影响[J]. 包装工程,2012,33(23):14-19. doi: 10.19554/j.cnki.1001-3563.2012.23.004.ZHAO D F,WEI D,ZHOU X Q,YING L S,ZHANG M.Effect of mixed moisture absorbers on quality of stored mushrooms in high oxygen modified atmosphere[J]. Packaging Engineering, 2012,33(23):14-19.doi:10.19554/j.cnki.1001-3563.2012.23.004.

[27] 赵月,陶乐仁,陈娟娟.吸湿剂及添加量对冷藏鲜辣椒品质的影响[J]. 江西农业学报,2014,26(11):105-108. doi:10.3969/j.issn.1001-8581.2014.11.029.ZHAO Y,TAO L R,CHEN J J.Effect of moisture absorber and its additive amount on quality of refrigerated fresh chilies[J]. Acta Agriculturae Jiangxi, 2014, 26(11):105-108. doi:10.3969/j.issn.1001-8581.2014.11.029.

[28] 赵亚,石启龙,王相友.复合吸湿剂优选及其对双孢蘑菇MA贮藏特性影响[J]. 食品工业(2015,36(12):154-159.ZHAO Y,SHI Q L,WANG X Y.Optimization of compound absorbers and its effects on MA storage characteristics of Agaricus bisporous[J].The Food Industry, 2015,36(12):154-159.

[29] 王成涛,王友升,肖俊松,李小东,曹雁平.高O2气调包装结合吸湿剂贮藏保鲜金针菇的条件优化及其效果研究[J]. 食品工业科技,2010(9):310-313. doi: 10.13386/j.issn1002-0306.2010.09.034.WANG C T,WANG Y S,XIAO J S, LI X D,CAO Y P.Optimization of condition and effects of HOAP combining hygroscopic agent on fresh-keeping of needle mushroom[J]. Science and Technology of Food Industry, 2010(9):310-313. doi:10.13386/j.issn1002-0306.2010.09.034.

[30] 蒋侬辉,刘伟,袁沛元,邱燕萍,向旭.荔枝保鲜包装技术研究进展[J]. 包装工程,2016,37(15):95-101. doi:10.19554/j.cnki.1001-3563.2016.15.019.JIANG N H,LIU W,YUAN P Y,QIU Y P,XIANG X.Research progress of fresh-keeping packaging technology of litchi[J].Packaging Engineering, 2016, 37(15):95-101. doi:10.19554/j.cnki.1001-3563.2016.15.019.